FMP 1 ½” to 6" Installation

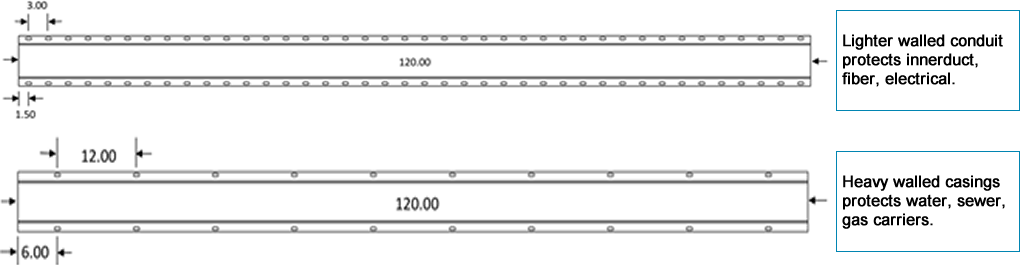

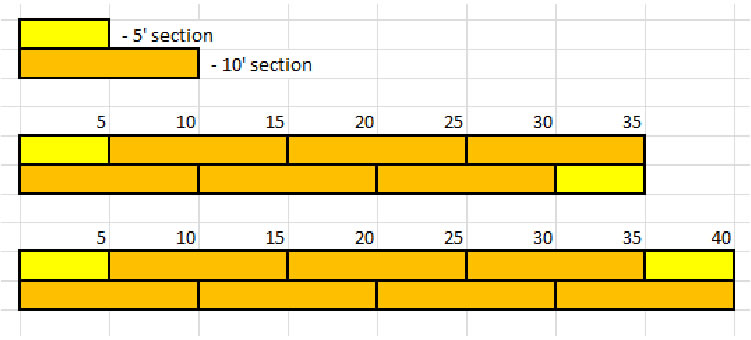

The FMP system is shipped in 10 ft. halves with anti-corrosive fasteners included, configured according to the flange bolting slot pattern indicated below (holes positioned on-center to allow field customization). Half sections can be ordered pre-cut into 5 ft. sections to enable staggered assembly, creating strength and eliminating the need for coupling. Labor savings of 50 - 75% have been reported from field installers.

FMP functions as a sleeve with I.D. that matches the O.D. of IPS-sized conduit and pipe, allowing FMP to be used to repair damaged conduit when bolted down to create a snug fit.

Ironhed FMP is installed using overlapped or staggered joint assembly. No couplers are required for straight runs.

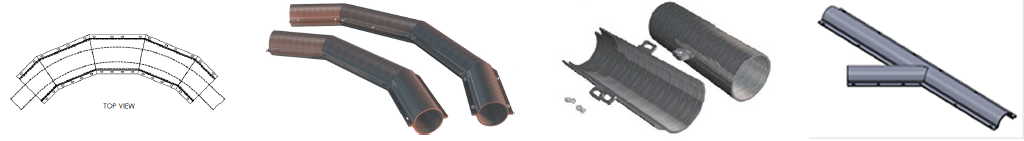

Mitered sweeps are available in standard bends of 11.25, 22.5, 30, 45, & 90 degrees, with radii of 18, 24, 30, & 36 in. plus custom sizes upon request. Internal Rotational Couplers are used to terminate FMP to standard manhole connections and FMP sweeps. WYE branches, reducing couplers, adaptors and other custom fittings are available.

When FMP is used as heavy casing pipe, spacers (available from Ironhed) are typically positioned every 6 ft. with appropriate clearance between the tops of the spacer’s runners and the inner wall of the FMP. Lifting eyes may be added at the factory to facilitate safer hoisting, placement, and adjustment.

Hours of operation: Monday through Friday 8:30 A.M. to 5:00 P.M. EST